CNC (Computer Numerical Control) technology has revolutionized manufacturing processes, offering unparalleled precision, efficiency, and automation. From its humble beginnings in the mid-20th century to today’s sophisticated systems, CNC has transformed industries worldwide. Let’s delve into the evolution of CNC and explore how LAKSH CREATIVE CNC Pvt Ltd remains at the forefront of this dynamic field.

Early Days of CNC:

The concept of numerical control emerged in the 1940s and 1950s, driven by the need for accurate and repeatable machining operations. Early CNC machines relied on punched cards to input instructions, a far cry from the intuitive software interfaces we have today. These machines were primarily used in aerospace and defense industries.

Advancements in CNC:

The introduction of computers in the 1960s marked a significant milestone in CNC technology. Computer Numerical Control (CNC) systems allowed for more complex and flexible programming. This led to increased adoption across various sectors, including automotive, electronics, and medical devices.

Modern CNC Systems:

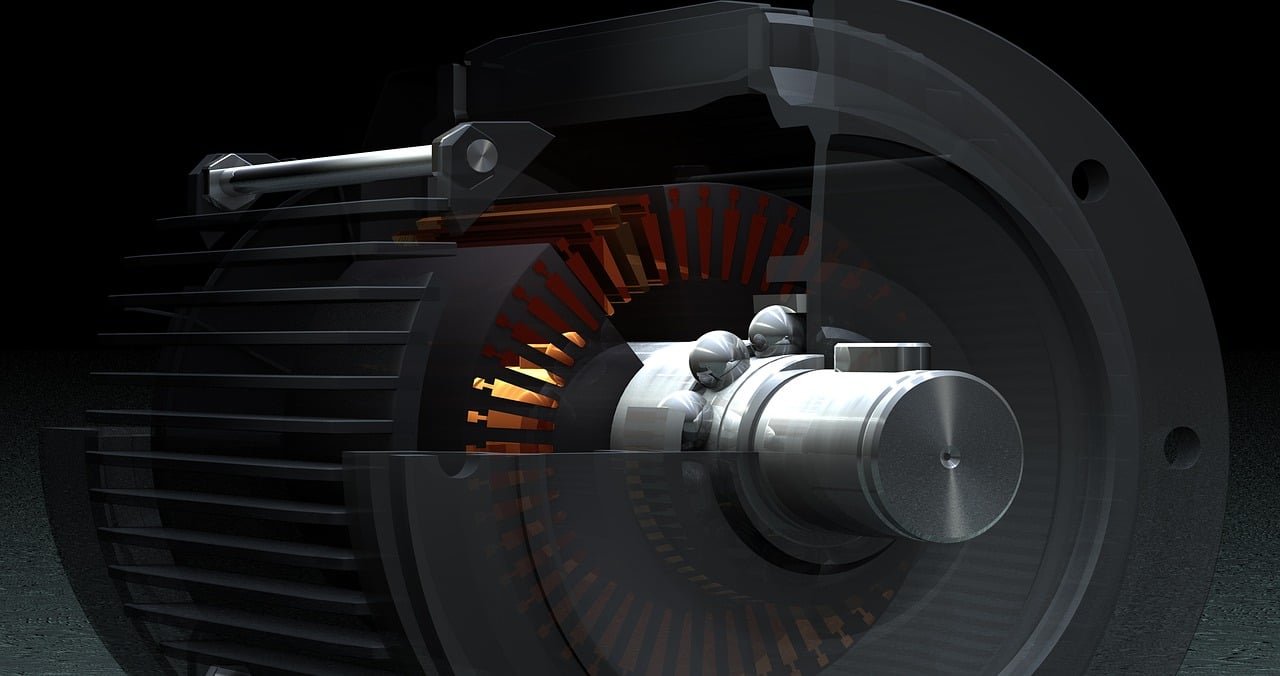

Today’s CNC machines are equipped with advanced features such as multi-axis machining, high-speed cutting, and real-time monitoring. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software plays a crucial role in designing and simulating parts before they are manufactured. This integration enhances accuracy, reduces waste, and accelerates production cycles.

LAKSH CREATIVE CNC Pvt Ltd’s Approach:

At LAKSH CREATIVE CNC Pvt Ltd, we understand the importance of staying ahead in the rapidly evolving CNC landscape. We continuously invest in state-of-the-art machinery, software, and training to deliver cutting-edge solutions to our clients. Our team of experienced engineers and technicians is adept at utilizing the latest CNC technologies to meet the most demanding manufacturing challenges.

Staying Ahead:

- Continuous Learning: We encourage our team to participate in training programs and industry events to stay informed about emerging trends and best practices.

- Technology Adoption: We regularly upgrade our equipment and software to incorporate the latest advancements in CNC technology.

- Innovation: We foster a culture of innovation, encouraging our employees to explore new techniques and solutions to improve our processes and services.