In today’s fast-moving business world, the margin for error is shrinking. Customers expect flawless products, faster delivery times, and cost-effective solutions. This is where CNC (Computer Numerical Control) technology becomes a game-changer. By combining automation, precision, and consistency, CNC is transforming industries of every scale.

What is CNC Technology?

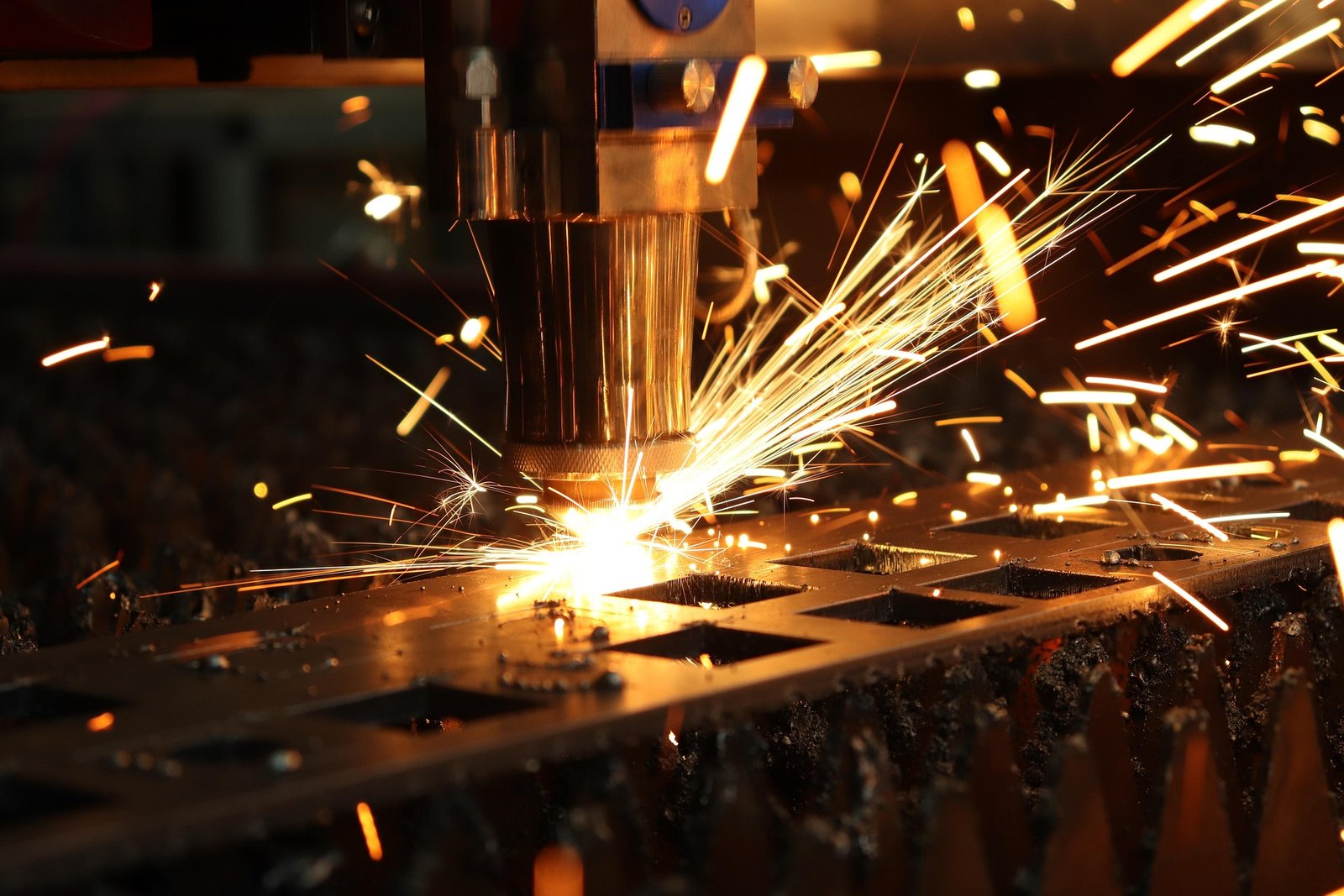

CNC is the process of using computer-controlled machines to cut, carve, or shape raw materials like wood, metal, acrylic, or plastic. Instead of relying on manual skills, CNC machines follow pre-programmed instructions with near-perfect accuracy.

Why Precision Matters in Business

-

Consistency: Every product is identical, which is crucial for mass production.

-

Time-Saving: CNC reduces production time by automating repetitive tasks.

-

Cost-Effective: Less waste, less error, and more efficiency save money in the long run.

Industries Using CNC

-

Furniture & Interior Décor: Complex patterns and custom panels.

-

Signage & Branding: Professional-quality logos and 3D lettering.

-

Automotive & Aerospace: Parts requiring micro-level accuracy.

-

Architecture: Scalable designs for construction projects.

Benefits Beyond Manufacturing

CNC technology also plays a vital role in sustainability by reducing material waste. Since every movement is calculated, businesses maximize resources, making it both eco-friendly and cost-efficient.

Conclusion

CNC technology is not just about machines—it’s about empowering businesses to grow, innovate, and lead in their markets.